Sat Jun 24 '17 Announcement

over 7 years ago

– Sat, Jun 24, 2017 at 12:52:00 PM

Hello backers!

Production is nearly done - read all about it:

100% stainless steel 3-in-1 vacuum flask, food container, thermal mug. Double wall vacuum insulated.

Hello backers!

Production is nearly done - read all about it:

We have another update for you! Please follow the link below to KickStarter - IndieGoGo update editor is very limited and buggy so we're unable to update you fully here.

KickStarter Forever Flask June production and shipping update

Hello backers and followers!

We're really happy and excited to announce that production has started!

We tested all the last engineering samples, quality was good, heat retention was good, we could not find any faults or reasons not to start production - so we started it.

Nothing really to report aside from this.

The timelines are as follows:

Finish production mid-end of June

Start shipping end of June

Backers start getting their rewards mid July

I have seen quite a few people ask about address changes and have been unlocking the surveys ad-hoc but will unlock all of them to make it easier.

Please note that you need to change your address in Backer Kit, NOT in KS/IGG.

That covers all the main things, here's to the final push to the finish line!

Mike Dewhirst

Hello wonderful backers and supporters!

We have received the (as we were hoping) final engineering samples last week.

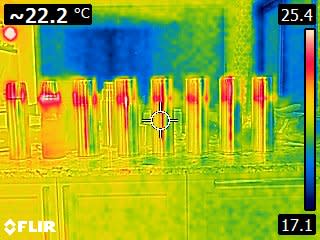

We have been testing them vigorously and we're super excited to report that they passed! Heat retention has been fantastic and we get around 75-80 C after 12 hours consistently. (that's with 95C water being poured in at the start)

There is also very little heat radiating externally as you can see on the attached photos.

So we're going to be...

...Starting production!!

(soon after we've tallied up all the colours, options, etc. A week or two including everybody in China getting ready to go)

Time-wise we hope to start production within the next 2 weeks and start shipping around beginning of June.

I will send another update soon with some photos of the updated units (not much in it, some small tweaks, the rest is not visible).

Thanks again for your continued support and patience and looks like we're nearly there!

All the best,

Mike Dewhirst

...Part 2

1) Upper part of the flask was too thin - as in the vacuum space between the outer and the inner wall - so too much heat was being lost through the top. As in the upper part of the flask was getting hot. And if it is - it is (too) rapidly loosing heat. The time heat was retained was OK an on par with other flasks +/- but we wanted to resolve this apparent issue. So we increased the vacuum space at the top (by making the inside a little smaller - probably loosing 100ml at most). BTW that’s extra manufacturing costs to make a new mould. This took a LOT of discussion, time and negotiation as we also considered changing the cap, the outer part of the flask - which would have cost a lot more and taken a lot longer - but decided to change the inside part only.

2) The cap was leaking a little so we made the silicone gasket a little (0.2mm) thicker to stop the leak. 1 out of 10 flasks still leaks so we may need to make it even thicker.

3) The o-ring on the lid (that stores bottom of the flask and also closes up the mug) was just sitting freely and as a result a) the o-ring would roll about and move down the lid and potentially come off and b) left a bit of a gap between the bottom of the flask and the lid and the mug and the lid. So the lid is now getting a recess where the o-ring will sit to ensure it does not move and also allow better closing of the lid into the bottom of the flask and top of the mug.

As things stand now, we’re looking at:

27th of March - complete mould modifications as per above changes. this is well under way now and started on the 25th of Feb

15th of April - a (hopefully) final batch of 10-15 engineering samples of flasks to arrive in UK for testing

25th of April - start production if above samples are approved

1st of June - production finished, shipping starts.

That’s all for now - feel free to ask any (constructive) questions, will do my best to answer quickly.

Thank you again for your support and patience!

Mike Dewhirst

P.s. if you read this far, put a comment in this update with a random word - to let me know you did and to make others think “what the heck?!” I’d like to see how many people read the update in full. I suspect it’s about 10-30 max.